This post includes an excerpt from the feature article in the Q2 2015 Forisk Research Quarterly (FRQ) Publication written by Amanda Lang, Brooks Mendell, David Garrett, and Heather Clark. The article analyzes global pellet demand and the implications for pine pulpwood prices across local timber markets in the U.S. South.

Wood pellets serve two primary end markets: residential for producing heat in homes and industrial power plants for generating electricity. While introduced in North America in the 1970s as an alternative fuel for industrial heat applications, current U.S. demand for pellets is exclusive to the residential market. Then, when wood pellets emerged as an option for reducing global carbon dioxide emissions at power plants, the U.S. emerged as a leading exporter of wood pellets from the South.

Forisk projects world demand for industrial wood pellets to grow from 10.6 million metric tons in 2014 to 25.0 million metric tons in the next five years, based on announced power plant conversions. The largest projected increases are in the UK and Denmark. U.S. export pellet capacity could increase from 5.0 million metric tons in 2014 to 10.7 million metric tons by 2019, based on project announcements that pass basic viability screening (have a viable technology and have achieved project development milestones). Projections indicate that U.S. wood pellet capacity would exceed the demand for U.S. wood pellets in the next three years, effectively “running ahead” of demand. There are two implications: (1) that pellet plants that plan to start-up in 2016 and 2017 will likely be delayed by one year, and (2) it is unlikely that additional export-focused pellet plants will be announced in the U.S. The players are at the table.

Additional demand impacts timber prices. Three demand-related factors drive local price changes: new wood bioenergy projects; existing and announced OSB capacity; and high volumes of softwood sawmill residual chips, which serve as a pulpwood substitute and mitigate price increases. Pulp and paper has always been and will continue to be the dominant user of pulpwood and chips in the South. In fact, pulp and paper account for approximately 80% of the pulpwood demand in the South in 10 years. Second, total peak pulpwood and chip use in 2019 and 2020 aligns with peak historic consumption in 1997 and 1998. So, pellet demand is basically replacing “lost” demand from pulp/paper in the projection at a regional (South-wide) level. In addition, increasing supplies of residual chips mitigate pulpwood price increases. South-wide, increased sawmill residual chips reduce projected pine pulpwood stumpage prices by $1.40 per ton on average, or by 11%, in the Q2 FRQ Base Case (compared with a scenario that does not include residual chips).

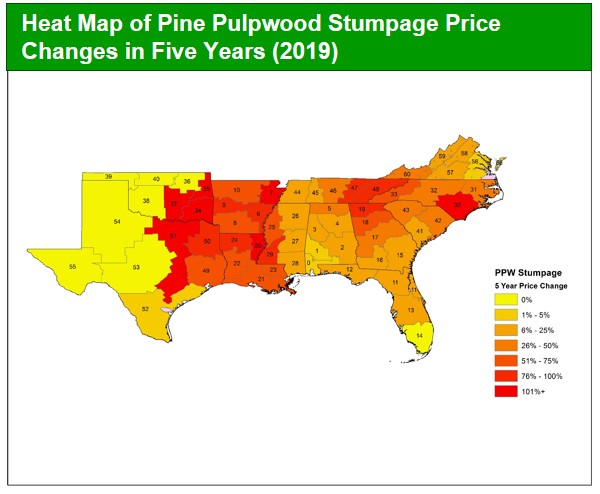

How might the projected changes in demand influence local pine pulpwood stumpage prices? Accounting for demand changes from the forest industry (which includes OSB, pulp/paper, and other industry participants) and bioenergy plants, stumpage prices could increase by 41% in the next five years in the South. This does not account for increasing residual chip supplies, which would dampen the price increase. The figure below highlights significant, estimated increases for pine pulpwood stumpage in the East Texas and Louisiana regions. This corresponds with large percentage increases in demand relative to today, while the larger, higher volume coastal markets are better able to absorb incremental demand growth.

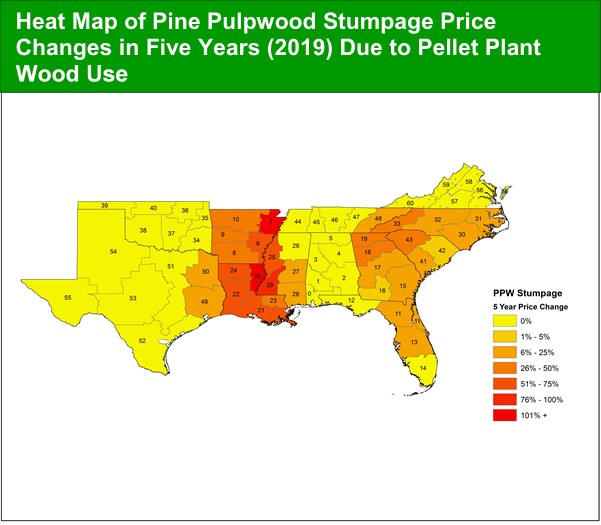

Increased demand from bioenergy plants could increase average stumpage prices in the U.S. South by 31% in the next five years, assuming no effect from increased residual chip supplies. This includes bioenergy announcements that pass viability screens, and 97% of the incremental demand from bioenergy plants is from pellet plant announcements. Effects vary greatly by state, from 0% price growth from bioenergy in Alabama and Tennessee to 50-55% in Mississippi and Arkansas and 84% in Louisiana.

Existing forest industry plants and announced capacity improvements at OSB and pulp/paper mills increase stumpage prices by an average of 19% for the South. North Carolina, Tennessee, Arkansas, and Texas have the greatest impacts from forest industry demand changes. It is important to note that price increases will be lower than reported in this article as residual chip supplies increase.

The primary bioenergy end-market that affects pine pulpwood stumpage prices is the pellet sector. Pellet plant openings could have the greatest impact on stumpage prices in the Gulf region (Louisiana, Arkansas, and Mississippi), with some effects in North Georgia and South Carolina, and in Florida and North Carolina (Figure below).

Once a small-scale industry that bagged pellets for homeowners to purchase in hardware stores, the U.S. wood pellet sector has evolved into a large-scale producer of pellets to ship across the Atlantic Ocean for power production. In aggregate, the impacts on pulpwood demand in the U.S. South projects to repeat a pattern of demand experienced in the late 1990s. However, the current situation has unique market exposures and different pulpwood price implications. Forest supplies look different locally: today, because of aggressive thinning and targeted pulpwood harvests during the recession, many local markets exhibit temporary tightness in pulpwood supplies. Wood users continue to wait for relief from increased residual supplies from sawmills. This relief would be real; these supplies represent a one-for-one substitute for and complement of pulpwood for most users. Politics matter: in projecting global pellet demand, we acknowledge the unpredictable yet impactful nature of regulations and legislative targets. Finally, markets and consumers adapt.

Leave a Reply