A few recent stories about automation pertain to the logging sector. First came a report by the World Economic Forum that automation might replace 5 million jobs in the next five years. While hardly a new trend, it seems to target lower-wage jobs. The McKinsey Global Institute was kind enough to convert some of the data into an interactive chart of occupations most readily replaced by automation. Logging equipment operators were listed as 100% automatable. That feels harsh. We have a long way to go before anyone trusts an artificial intelligence to thin their pine plantations, much less their high-value hardwood stands. But with the slow, steady progress in self-driving cars, is the self-driving skidder mere decades away?

On the back of those sobering statistics comes news that Caterpillar has been successfully operating their feller-bunchers remotely in a harvesting project on Fort Bragg. Three tracked machines are clearing a 900-acre ordinance range, with the operators sitting in a trailer far from the dangers of bombs, artillery and Army Rangers. It represents an impressive leap forward in remote harvesting operations. Little question exists that this first step is geared towards protecting the safety of operators in unique harvesting situations. The careful selection of individual trees with an eye towards preserving their optimum value and minimizing stand damage probably had lower priority. Still, it is a clear proof of the concept. Also, it might be easier to recruit new logging equipment operators if they can work from home.

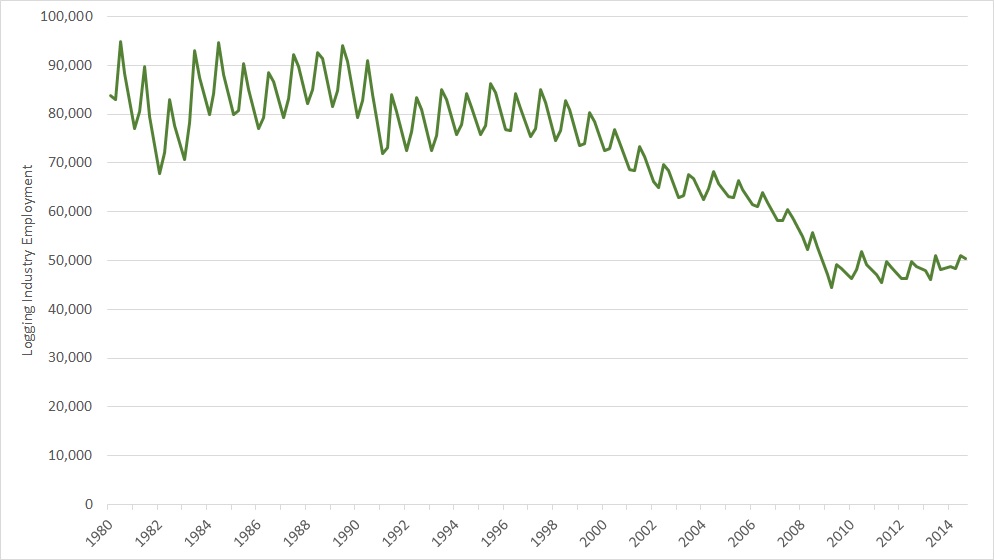

All of this evidence indicates that the logging sector, still wrongly viewed by many in the public as lumberjacks swinging axes, is becoming more and more technically advanced. Labor remains the primary cost in logging, accounting for one-third or more of the total cost to put wood on a truck to the mill. As younger generations appear less inclined to take jobs in the woods, the move to automation offers two possible benefits. It fills a job which has become harder to fill and (maybe) lowers the cost of the operation. Mechanization has drastically reshaped the logging sector, shrinking the number of workers needed to meet our wood demands. Might automation be the next step in this process?

Source: Bureau of Labor Statistics

Featured research in the Q1 2016 FRQ discusses recent trends in logging employment and examines drivers of logging capacity. To learn more about the Forisk Research Quarterly (FRQ), click here or call Forisk at 770.725.8447.

Interesting topic. I’ve followed the development of Google’s self-driving cars with interest over the last few years, but given little thought to applications of the same technology in logging equipment. Automated logging technology wouldn’t come cheap, but imagining the implications of a “crew” that could work 24/7 with no breaks is tantalizing.

When I started as an intern in 2004, my company still had a father/son team that worked with chainsaws and hauled one load at the end of each day. When I left my harvest manager position in 2014, I didn’t have a single crew who used a chainsaw on a regular basis. In that context, automated logging doesn’t seem like it should be too far off.