Early in my wood procurement career, my friend and timber buyer Fred Voyles taught me that, as a forester buying logs for a mill, to really learn and have an impact, to improve a situation or reinforce an expectation, to show you know what’s going on and to demonstrate respect (that’s a lot of things 🙂 ), you have to get out of the truck.

At Forisk, we spend a lot of time “out of the truck” in operations, collecting data, talking with people and testing ideas. The research shared at our Wood Flows & Cash Flows events and in the Forisk Research Quarterly reflect this approach. This post is the first in a series that shares specific learnings and observations from spending months visiting dozens of wood-using mills and in-woods operations with one firm, PalletOne, to highlight challenges and approaches potentially relevant to the success of the entire forest industry.

What is a Pallet?

Pallets solve problems in a world reliant on shipping containers to move product. Unlike crates or barrels, pallets provide a stable platform that plays nicely with forklifts, loaders and other crane-like machines that must move and store heavy stacks. Any stroll through a warehouse or the back end of a big box store will find dozens and hundreds of pallets loaded with corrugated boxes coming from or headed to containers and semis.

Figure 1. Wood Pallets Ready to Ship and Load

Photo by B. Mendell taken at PalletOne in Shipshewana, Indiana

Pallets, like those pictured above, are the wooden Lego pieces and “moving trays” used to transport humanity’s consumables, from bricks to books to orange crates and cases of beer. In short, no pallets, no Super Bowl parties.

PalletOne and the U.S. Wood Pallet Sector

The wood pallet business simultaneously fills a niche and sits in a sandwich. The niche absorbs low-grade hardwood logs and low-grade pine lumber to manufacture pallet stock and pallets for moving products around the world. On the hardwood side, the pallet sector absorbs the boards and logs not good enough to produce flooring or veneer or cabinets. On the pine side, pallets absorb the boards that fail to make the cut for the building and remodeling of homes, or any appearance grade applications.

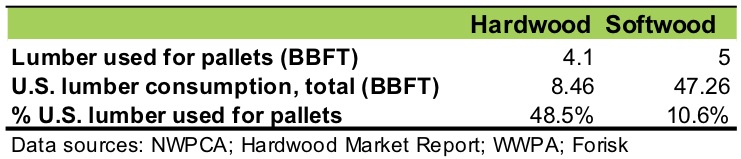

According to research from the National Wood Pallet and Container Association (NPWCA), U.S. pallet manufacturers produced 849 million wood pallets in 2016 (508 million new and 341 million recycled), or 14% more than five years earlier. Figure 2 summarizes the volumes of hardwood and softwood lumber required to manufacture these pallets. Softwood lumber accounts for more than half (55%) of wood pallet lumber raw materials, but pallets account for under 11% of U.S. softwood lumber consumption (and just over 15% of U.S. softwood lumber production). Alternately, wood pallets account for nearly 49% of hardwood lumber applications.

Figure 2. Lumber Used for Wood Pallets in the U.S. (2016)

In the U.S., PalletOne is the largest new wood pallet manufacturer. The firm operates 16 locations in 9 states and manufactures new hardwood and softwood pallets, repairs and recycles used pallets and produces a range of other wood products. Across its operations, PalletOne employs over 1,500 people at 20 locations.

Over the past two years, we’ve had the chance to get out of the truck and visit two dozen PalletOne manufacturing and in-woods operations. Physical facts and new realities related to forest supplies, labor, and technology change the way PalletOne sees and navigates its business, and offers useful lessons for those of us thinking through forest industry strategy.

We introduce these lessons in Part II.

Leave a Reply