This post is the second in a series related to the Q1 2022 Forisk Research Quarterly (FRQ). It includes topics that will also be addressed in the (virtual) Applied Forest Finance course on May 19th, 2022.

Forest carbon opportunities profit from markets which trade on the mismatch between energy use (what we consume) and the greenhouse gas emissions associated with current industries (what we produce and how). [This oddly echoes the paleo diet, which specifies the mismatch between a “natural” diet (what we eat) and modern processed foods (what we make).]

However, the understanding of and markets for forest carbon remain in progress. Carbon capture and storage by trees varies based on forest age, trees planted per acre and management strategy. Compare the active CO2 sequestration of younger virile and established forests with the slow CO2 intake and release by old stands, dying trees and forest fires.

The potential for narrow views and limitations from evolving carbon markets frustrates forest industry decision-makers. One executive said, “I feel these carbon programs expect us to simply reduce harvesting… and eat higher delivered wood costs. And for what?” As this person noted, the rapid growth in U.S. voluntary carbon markets, and the associated supply increase in forest carbon credits, has resulted in falling prices for these credits in some programs.

Let us then step back and consider a broader view that says forest carbon benefits do not end “in the woods.” The optimal path for capturing carbon includes active, sustainable forest management and harvesting combined with the production of solid wood products. Well managed forests plus the use of long-lived wood products leverages the portfolio of carbon storage possibilities from trees throughout the supply chain and across the economy.

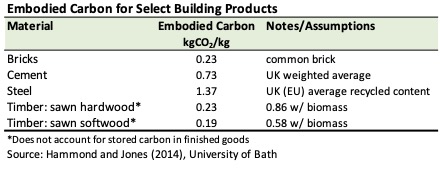

Wood products perform well relative to other building materials in head-to-head comparisons of embodied carbon, which estimate in kilograms of CO2 per kilogram of product the attributable carbon emissions for its life cycle, from extraction to manufacturing to use and, finally, disposal. Ongoing research by Professor Geoffrey Hammond and Craig Jones at the University of Bath in the UK supports the Inventory of Carbon and Energy (ICE) open-access data for embodied energy and carbon associated with a wide range and forms for construction materials. The table compares a few products to hardwood and softwood lumber.

A cursory review of the table highlights the low (that’s good) embodied carbon associated with timber versus steel, in particular. However, even this understates the relative benefits of wood. For example, the ICE database focuses on “cradle-to-gate” versus “cradle-to-grave.” This means that for timber products, the data does not account for the benefits of carbon storage, which would further reduce the embodied carbon factors.

[Note: the newest ICE data also separates the embodied carbon into two components: one from burning fossil fuels and a second from burning biomass. The numbers summed provide a total “cradle-to-gate” for carbon released, which would be appropriate in cases where the wood is sourced from unsustainably managed forests.]

For another example, we looked to CORRIM which conducted a study comparing wood-framed homes with alternate materials in cold and warm climates. Overall, wood-framed homes use less energy than steel or concrete projects, even accounting for hauling inbound and out, and does more, on a relative basis, to reduce greenhouse gas emissions.

Forest carbon provides opportunities for investors and firms interesting in assessing the “portfolio of options” available to them, from forest management to solid wood products.

Probably also have to include through life cost accounting for the fact that timber buildings are more energy efficient especially in colder regions. In a lfl comparison mass timber construction uses a 10 th of the heating energy that concrete requires.

The view of NCX is that all stored carbon is emitted on harvest because “more carbon is emitted in the processing of these materials than is stored in the materials themselves.” Have you reconciled your view with theirs?

Jim: thank you for the note and question. I don’t view these perspectives as mutually exclusive; rather, they speak to different questions. I am extremely interested in relative performance and continuous improvement (for investment assets, processes, businesses, my handwriting (which is horrible)). Assuming we continue to build homes and offices, and in the context of choosing which activities or materials get us closer to benign industrial activities, the question becomes, “well, should we use wood or steel?” – Brooks