The U.S. enjoys a wide range of natural diversity. This makes touring through our national parks such a fulfilling exercise. That diversity also presents challenges if you need to operate a high-production operation in the natural environment. Uniformity is the key to operational efficiency, a lesson we learned from Eli Whitney, Henry Ford and generations of production experts. Planted forest stands on level ground are the closest the logging industry gets to a uniform operating environment, but that only represents a small proportion of the sites from which our forest products originate. As such, the types of equipment best suited to a harvest site and the cost of operations will vary.

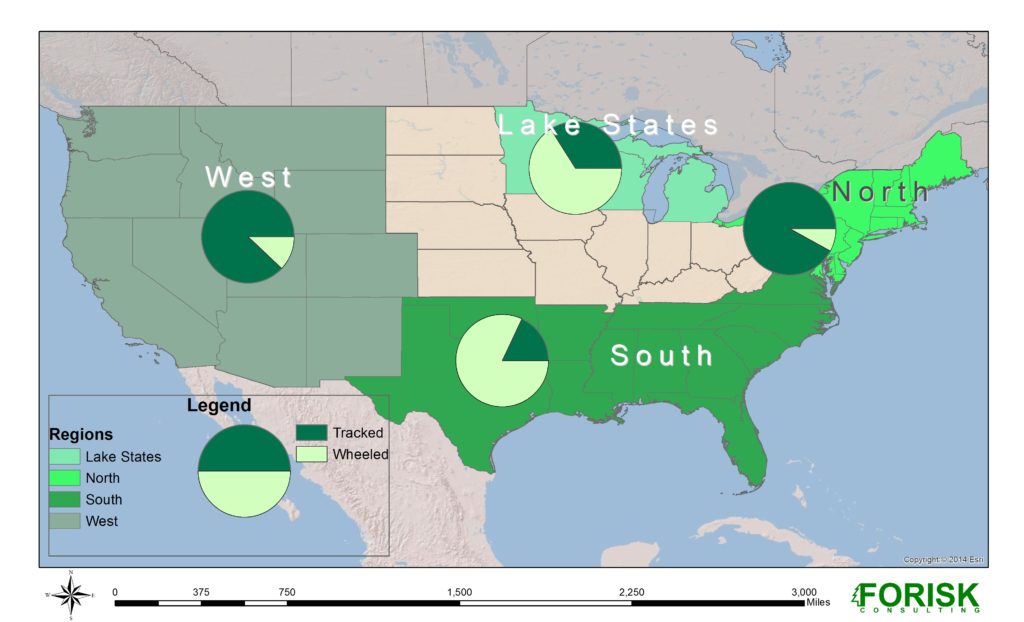

At Forisk, we forecast logging costs in local wood markets by assessing the types of systems that might operate in a given geography. Unfortunately, on-the-ground data is remarkably difficult to come by. To offer a little clarity, we collected data on used equipment markets across the country to examine the prevalence of different harvesting systems. We used tree-length harvesting systems as our starting point and considered wheeled, drive-to-tree feller bunchers, which are less expensive but require firm, level terrain, versus tracked, swing-to-tree feller bunchers which cost more but can handle more challenging operating conditions (Figure 1). The prevalence of those two types of machines varies substantially across the country (Figure 2). In the North and West, swing-to-tree machines were far more prevalent than in the South.

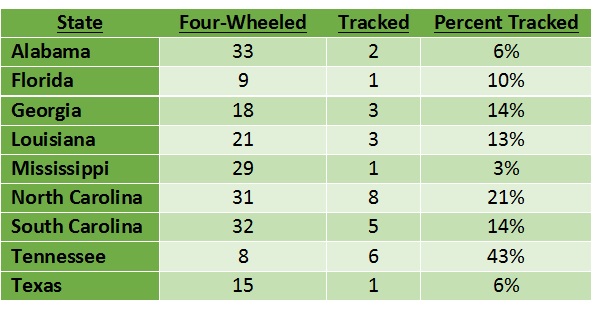

Even within the South, we saw variation in the presence of swing-to-tree machines (Figure 3). North Carolina had the highest proportion of tracked feller bunchers outside of Tennessee. With wet ground harvesting in the east and steep terrains in the west, North Carolina is a sensible location for more swing-to-tree operations. It also implies harvesting costs may be slightly higher there, on average, to cover the additional investment required for a tracked feller buncher.

Our forest operations research supports analysis of logging costs and timber prices, and are a component of the Forisk Research Quarterly (FRQ). To learn more about the FRQ, click here or contact Brooks Mendell at bmendell@forisk.com, 770.725.8447.

Forisk intern Chantal Tumpach supported the research for this blog post.

Leave a Reply