This post is the fourth in a series related to the Q2 2019 Forisk Research Quarterly

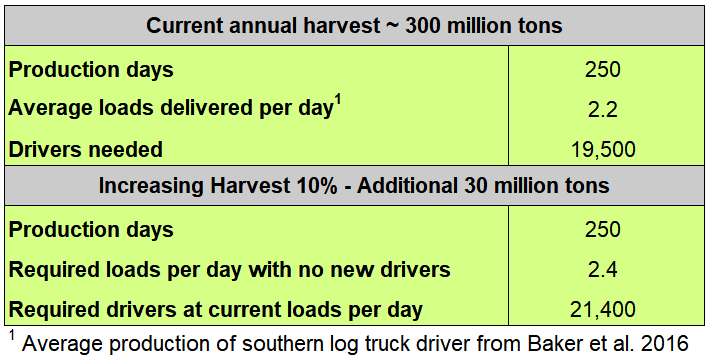

Forisk forecasts an additional 3 BBFT of sawmill capacity in the South over the next three years. If trucking is strained, how do we move an additional 13 million tons per year? One load at a time, of course. However, the idea of hiring 800 more truck drivers seems daunting in the current labor market. So, can the industry better utilize the drivers we currently have to meet the demand?

Regionally, if each truck picks up two more loads per month, we’re there (See Figure). Unfortunately, sawmill expansions are not evenly distributed across the South. They are tied to specific locations. If they locate in wood basins with trucking capacity constraints, incremental improvements in utilization will fail to solve the problem.

If we operated in a fixed world, where every truck is either loaded or on its way to reload, then the wood supply system is strung tight. In reality, the wood supply chain is not great at trucking. Production swings wildly because of weather, breakdowns, quotas, etc. At times, we could operate with 5,000 fewer drivers, at other times 5,000 more would be insufficient. Today, there is a logger somewhere sitting idle, unable to haul. Ideally, they would make up lost production when conditions improve. The challenge of constrained trucking capacity is there is no ability to “surge” in production to make up for lost days.

Figure. Example Impact of Improved Efficiency in Hauling

Trucking cannot be viewed as a necessary evil, and solutions are no longer simple. Asking drivers to add hours to supplement lost trucking capacity is not a solution. Hauling inefficiency (in woodyards and in-the-woods) remains common. Inefficiencies cost the entire supply chain. A logger or mill who takes 20 minutes longer than average to turn trucks adds an hour a day to every truck. If drivers average 2.2 loads and 11 working hours per day, that extra hour costs 0.2 loads per day or a load a week. The Figure above demonstrates that such an impact can amount to 30 million tons of additional wood if applied to every driver. That would feed a lot of sawmills.

The wood supply chain must consider multi-faceted solutions to the problem. There is no silver bullet.

- Take care of current drivers. By far, the first step is to retain the capacity we have. Truck drivers currently have other options. Salaries, benefits and quality of life are all areas that affect decisions to leave a current job.

- Ruthlessly evaluate your operations. Inefficiency multiplies throughout our system. When trucking is the bottleneck, any negative impacts to trucks affect cost and productivity of all links in the supply chain.

- Hire whenever possible. In the current job environment, there are not a lot of qualified, quality employees sitting at home. Always be open to opportunities, wherever you hear about them.

To learn more about the Forisk Research Quarterly (FRQ), click here or call Forisk at 770.725.8447.

Leave a Reply